what to do ?

- loudhvx

-

- Offline

- KZr Legend

-

Registered

- Posts: 10863

- Thanks: 1622

Re: what to do ?

24 May 2016 11:04Please confirm how you did the compression test. Did you do what Ed said?650ed wrote: You may not have tested the compression properly. To do so :

The engine must be warmed up to normal operating temperature. The pistons taper in near the top so with the engine warmed up they expand near the top which helps the rings seal against the cylinder walls.

The battery needs to be fully charged.

The throttle needs to be held all the way open.

All spark plugs must be removed.

If you do all that and compression is still low you should perform a leak down test. That will identify where the compression is leaking (could be valves, rings, head gasket, etc.) If you remove the cylinder head before performing the leak down test you will have lost the opportunity to use that diagnostic tool.

Ed

Does your compression gauge have a check valve in the tip? If not, that will cause low readings.

1981 KZ550 D1 gpz.

Kz550 valve train warning.

Other links.

Kz550 valve train warning.

Other links.

Please Log in or Create an account to join the conversation.

- loudhvx

-

- Offline

- KZr Legend

-

Registered

- Posts: 10863

- Thanks: 1622

Re: what to do ?

24 May 2016 11:07

1981 KZ550 D1 gpz.

Kz550 valve train warning.

Other links.

Kz550 valve train warning.

Other links.

Please Log in or Create an account to join the conversation.

- loudhvx

-

- Offline

- KZr Legend

-

Registered

- Posts: 10863

- Thanks: 1622

Re: what to do ?

24 May 2016 11:11

The float needle's seat does have a gasket.

I don't really want to repeat the service manual on my site. But my site does show the gasket.

I don't really want to repeat the service manual on my site. But my site does show the gasket.

1981 KZ550 D1 gpz.

Kz550 valve train warning.

Other links.

Kz550 valve train warning.

Other links.

Please Log in or Create an account to join the conversation.

- zirafin

-

Topic Author

Topic Author

- Offline

- User

-

Registered

- Posts: 86

- Thanks: 1

Re: what to do ?

24 May 2016 11:15

o ring is on jet holder sorry if i write wrong .

and gasket is on picture but not all can see special me

and gasket is on picture but not all can see special me

Please Log in or Create an account to join the conversation.

- zirafin

-

Topic Author

Topic Author

- Offline

- User

-

Registered

- Posts: 86

- Thanks: 1

Re: what to do ?

24 May 2016 11:20

compression i was doing : warm engine . tace out spark plugs and test . i can do it tomorrow again , after i test the carburetor if missing o rings and gaskets then valve clearance , and then compression again.

Please Log in or Create an account to join the conversation.

- loudhvx

-

- Offline

- KZr Legend

-

Registered

- Posts: 10863

- Thanks: 1622

Re: what to do ?

24 May 2016 11:26

Ed said the throttle must be held wide open during the test.

Did you do that?

Did you do that?

1981 KZ550 D1 gpz.

Kz550 valve train warning.

Other links.

Kz550 valve train warning.

Other links.

Please Log in or Create an account to join the conversation.

- zirafin

-

Topic Author

Topic Author

- Offline

- User

-

Registered

- Posts: 86

- Thanks: 1

Re: what to do ?

24 May 2016 11:41 - 24 May 2016 11:41

ok so it not enough to use choke on . ok i will try to throttle go all open ( i hope i understand u its throttle-in picture)

Attachment index.jpeg not found

Last edit: 24 May 2016 11:41 by zirafin.

Please Log in or Create an account to join the conversation.

- loudhvx

-

- Offline

- KZr Legend

-

Registered

- Posts: 10863

- Thanks: 1622

Re: what to do ?

24 May 2016 12:23 - 24 May 2016 12:24yes.zirafin wrote: ok so it not enough to use choke on . ok i will try to throttle go all open ( i hope i understand u its throttle-in picture)

Attachment index.jpeg not found

Choke open all the way.

Throttle open all the way.

1981 KZ550 D1 gpz.

Kz550 valve train warning.

Other links.

Kz550 valve train warning.

Other links.

Last edit: 24 May 2016 12:24 by loudhvx.

Please Log in or Create an account to join the conversation.

- zirafin

-

Topic Author

Topic Author

- Offline

- User

-

Registered

- Posts: 86

- Thanks: 1

Re: what to do ?

24 May 2016 23:43 - 24 May 2016 23:44

hi

carbs its ok all parts is in.

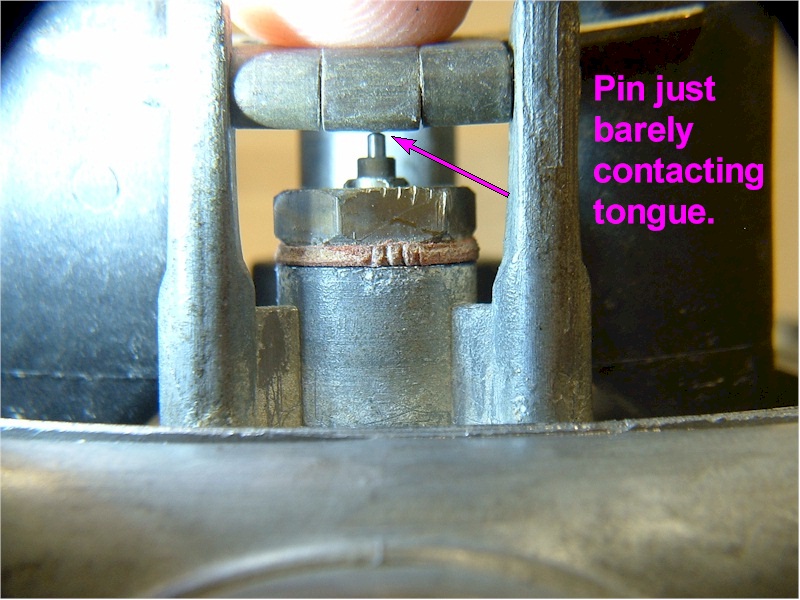

valve clearance : picture . i turn using 17 wrench each valve lift up and test .

carbs its ok all parts is in.

valve clearance : picture . i turn using 17 wrench each valve lift up and test .

Attachment IMAG1456.jpg not found

Attachment IMAG1450.jpg not found

Attachment IMAG1455.jpg not found

Attachment IMAG1452.jpg not found

Last edit: 24 May 2016 23:44 by zirafin.

Please Log in or Create an account to join the conversation.

- zirafin

-

Topic Author

Topic Author

- Offline

- User

-

Registered

- Posts: 86

- Thanks: 1

Re: what to do ?

24 May 2016 23:45

what kind of shims do i need i fink its will be very hard to gen for me .only on ebay .

Please Log in or Create an account to join the conversation.

- zirafin

-

Topic Author

Topic Author

- Offline

- User

-

Registered

- Posts: 86

- Thanks: 1

Re: what to do ?

25 May 2016 02:20 - 25 May 2016 04:33

so on cylinder 4 on ex side its stuck the cup . i will try to tace out using the magnet . i use tools.but its go out .

Attachment IMAG1457.jpg not found

Last edit: 25 May 2016 04:33 by zirafin.

Please Log in or Create an account to join the conversation.

- zirafin

-

Topic Author

Topic Author

- Offline

- User

-

Registered

- Posts: 86

- Thanks: 1

Re: what to do ?

25 May 2016 04:39 - 25 May 2016 05:06

after i tace out i use micrometer .in picture its write shim thickness from 1 til 8 in black color.

from manual valve clearance its

ex 0.15-0.25mm

in 0.10-0.20 mm

so if i want new shims to mace at metalworkers

i do :

1. 0.15mm is valve clearance i need to have 0,20 mm

0.20-0.15=0.05 mm

shim is standing under cup 2.44 mm

2.44-0.05=2.39mm2.38mm

so i need to make 2.39 mm 2.38 mm shim

next shims i have on paper :

its ok o i need others shims o i can grind shims at metalworkers???

from manual valve clearance its

ex 0.15-0.25mm

in 0.10-0.20 mm

Attachment IMAG1460.jpg not found

so if i want new shims to mace at metalworkers

i do :

1. 0.15mm is valve clearance i need to have 0,20 mm

0.20-0.15=0.05 mm

shim is standing under cup 2.44 mm

2.44-0.05=2.39mm2.38mm

so i need to make 2.39 mm 2.38 mm shim

next shims i have on paper :

Attachment IMAG1462.jpg not found

its ok o i need others shims o i can grind shims at metalworkers???

Last edit: 25 May 2016 05:06 by zirafin.

Please Log in or Create an account to join the conversation.

Moderators: Street Fighter LTD