Z1000R and Z1000J - Lots of pics, and Gun-Kote oven baked paint.

- RoyNor

-

Topic Author

Topic Author

- Offline

- User

-

Registered

- Posts: 359

- Thanks: 1

Re: Z1000R and Z1000J - Lots of pics, and Gun-Kote oven baked paint.

19 Jan 2009 13:47

Thanks Calhoun.

Well, the bike looks still pretty much like an frame with an engine on, hehe.

But slowly, I am working on the the details!

Today i sent the sprocket carrier to MR 531 blackbanshee, he will mill the carrier down a few mm. :woohoo:

I do not know the ground clearance after everything is mounted up, maybe some other here knows?

But here is an old pic with the length of the fork, from center bolt to top of the fork.

Well, the bike looks still pretty much like an frame with an engine on, hehe.

But slowly, I am working on the the details!

Today i sent the sprocket carrier to MR 531 blackbanshee, he will mill the carrier down a few mm. :woohoo:

I do not know the ground clearance after everything is mounted up, maybe some other here knows?

But here is an old pic with the length of the fork, from center bolt to top of the fork.

Please Log in or Create an account to join the conversation.

- 531blackbanshee

-

- Offline

- Vendor

-

Vendors

- Posts: 7444

- Thanks: 796

Re: Z1000R and Z1000J - Lots of pics, and Gun-Kote oven baked paint.

19 Jan 2009 14:00

roy,in the picture showing where the brake stay should be there appear to be some of those compression nuts(nuts that go in a hole through sheet metal or thin material and then you tighten them up and they collapse inside and hold on to the material)i can get some of those if you need some to possibly bolt the anchor and maybe shock mounts on.we might have to do some custom brackets but then you could bolt them on and not have to visit(pay) the welder dude.just a thought.

leon

leon

skiatook,oklahoma 1980 z1r,1978 kz 1000 z1r x 3,

1976 kz 900 x 3

i make what i can,and save the rest!

billybiltit.blogspot.com/

www.kzrider.com/forum/5-chassis/325862-triple-tree-custom-work

kzrider.com/forum/5-chassis/294594-frame-bracing?limitstart=0

1976 kz 900 x 3

i make what i can,and save the rest!

billybiltit.blogspot.com/

www.kzrider.com/forum/5-chassis/325862-triple-tree-custom-work

kzrider.com/forum/5-chassis/294594-frame-bracing?limitstart=0

Please Log in or Create an account to join the conversation.

- RoyNor

-

Topic Author

Topic Author

- Offline

- User

-

Registered

- Posts: 359

- Thanks: 1

Re: Z1000R and Z1000J - Lots of pics, and Gun-Kote oven baked paint.

20 Jan 2009 04:06 - 20 Jan 2009 04:08

Leon!

Thats a really nice idea! :woohoo:

I thought the aluminum couldnt be bolted on because of the material.

I guess the brackets still need to be aluminum, its no good to mix alu and steel?

Or does that still count as long the materials are bolted on and not welded?

Thats a really nice idea! :woohoo:

I thought the aluminum couldnt be bolted on because of the material.

I guess the brackets still need to be aluminum, its no good to mix alu and steel?

Or does that still count as long the materials are bolted on and not welded?

Last edit: 20 Jan 2009 04:08 by RoyNor.

Please Log in or Create an account to join the conversation.

- 531blackbanshee

-

- Offline

- Vendor

-

Vendors

- Posts: 7444

- Thanks: 796

Re: Z1000R and Z1000J - Lots of pics, and Gun-Kote oven baked paint.

20 Jan 2009 09:29

roy,

you can bolt dissimilar metals together.you cannot weld dissimilar metals together.(unless the are alloys of each other.)i would not want to drill and tap the aluminum itself but i would feel totally safe using the compression nuts on shock mounts.we could build the shock brackets with tabs sticking out front and back for the bolt holes and to spread the load.or ship it over here and i will weld them on for you:P . you know me roy anything to help a fellow zedhead :evil:

leon

you can bolt dissimilar metals together.you cannot weld dissimilar metals together.(unless the are alloys of each other.)i would not want to drill and tap the aluminum itself but i would feel totally safe using the compression nuts on shock mounts.we could build the shock brackets with tabs sticking out front and back for the bolt holes and to spread the load.or ship it over here and i will weld them on for you:P . you know me roy anything to help a fellow zedhead :evil:

leon

skiatook,oklahoma 1980 z1r,1978 kz 1000 z1r x 3,

1976 kz 900 x 3

i make what i can,and save the rest!

billybiltit.blogspot.com/

www.kzrider.com/forum/5-chassis/325862-triple-tree-custom-work

kzrider.com/forum/5-chassis/294594-frame-bracing?limitstart=0

1976 kz 900 x 3

i make what i can,and save the rest!

billybiltit.blogspot.com/

www.kzrider.com/forum/5-chassis/325862-triple-tree-custom-work

kzrider.com/forum/5-chassis/294594-frame-bracing?limitstart=0

Please Log in or Create an account to join the conversation.

- tachrev

-

- Offline

- User

-

Registered

- Rubber Side Goes Down

- Posts: 338

- Thanks: 11

Re: Z1000R and Z1000J - Lots of pics, and Gun-Kote oven baked paint.

20 Jan 2009 11:54

531blackbanshee wrote:

Are the compression nuts you are talking about something that would be available at a Lowes, ACE, or other hardware store?

roy,

you can bolt dissimilar metals together.you cannot weld dissimilar metals together.(unless the are alloys of each other.)i would not want to drill and tap the aluminum itself but i would feel totally safe using the compression nuts on shock mounts.we could build the shock brackets with tabs sticking out front and back for the bolt holes and to spread the load.or ship it over here and i will weld them on for you:P . you know me roy anything to help a fellow zedhead :evil:

leon

Are the compression nuts you are talking about something that would be available at a Lowes, ACE, or other hardware store?

1977 Kawasaki KZ1000 : Street/Strip

Build Thread

Build Thread

Please Log in or Create an account to join the conversation.

- RoyNor

-

Topic Author

Topic Author

- Offline

- User

-

Registered

- Posts: 359

- Thanks: 1

Re: Z1000R and Z1000J - Lots of pics, and Gun-Kote oven baked paint.

20 Jan 2009 13:31 - 20 Jan 2009 13:36

Shipping that swing is not an option, you know the shipping prices US <-> Norway.

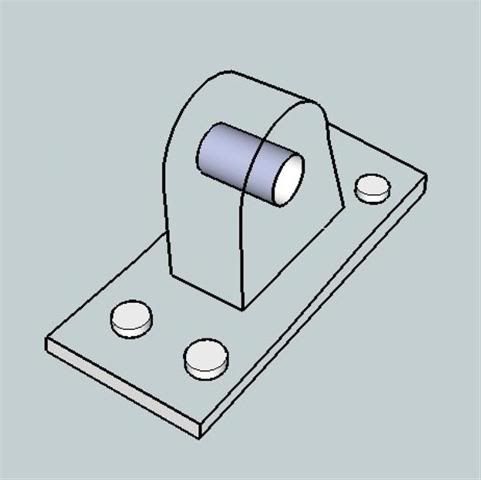

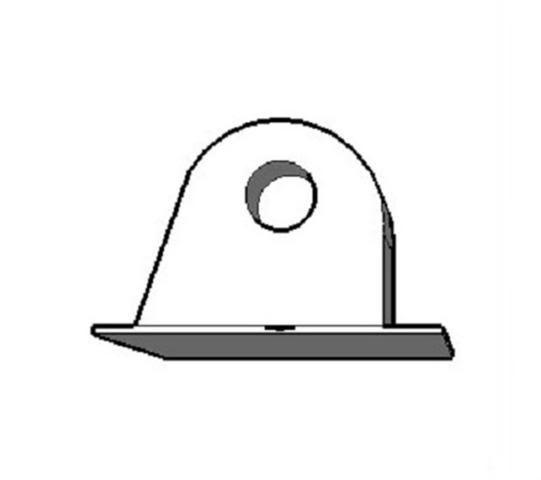

But using those compression nuts are, so we have to find an design on the shock mounts then.

First we have to decide which shocks to use.

The Suzuki style...

The Kawa...

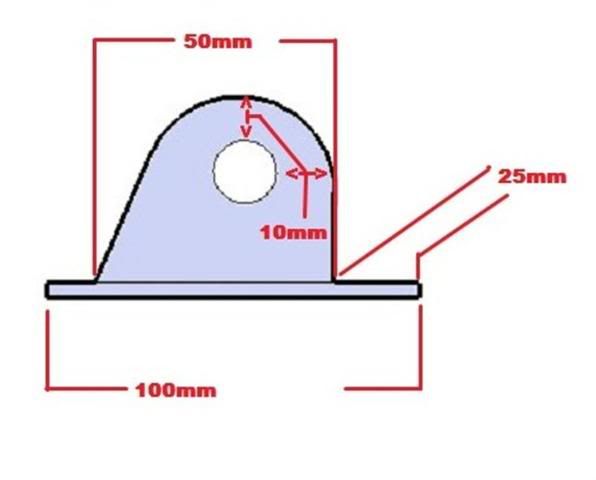

The measurements.

The corners are rounded, so its 30mm to start of each corner.

30mm X 80mm, for example...?

And I guess this is what we are talking about?

But using those compression nuts are, so we have to find an design on the shock mounts then.

First we have to decide which shocks to use.

The Suzuki style...

The Kawa...

The measurements.

The corners are rounded, so its 30mm to start of each corner.

30mm X 80mm, for example...?

And I guess this is what we are talking about?

Last edit: 20 Jan 2009 13:36 by RoyNor.

Please Log in or Create an account to join the conversation.

- RoyNor

-

Topic Author

Topic Author

- Offline

- User

-

Registered

- Posts: 359

- Thanks: 1

Re: Z1000R and Z1000J - Lots of pics, and Gun-Kote oven baked paint.

20 Jan 2009 13:51Please Log in or Create an account to join the conversation.

- 531blackbanshee

-

- Offline

- Vendor

-

Vendors

- Posts: 7444

- Thanks: 796

Re: Z1000R and Z1000J - Lots of pics, and Gun-Kote oven baked paint.

21 Jan 2009 14:10

tachrev,

they are actually called "nutserts"here is a link to them.

www.imperialinc.com/grp270.shtml

they are at the bottom of the page.i am not sure about the local hardware store availability.i work in a forklift dealership and they are widely used to mount headlights and fire extinguishers to the driver overhead guards on forklifts.i have used them and thought they we're neat and been on the lookout for an application in which to utilize them.when i saw what roy was doing the light came on:laugh: .

roy,if you can imagine the mounts you showed that z1e sells we would mill some billet ones out like those, except these would have tabs out the front and rear to drill holes through to bolt the mounts down.and could also have a series of threaded holes spaced apart to use to lower the bike with.just a thought.

leon

they are actually called "nutserts"here is a link to them.

www.imperialinc.com/grp270.shtml

they are at the bottom of the page.i am not sure about the local hardware store availability.i work in a forklift dealership and they are widely used to mount headlights and fire extinguishers to the driver overhead guards on forklifts.i have used them and thought they we're neat and been on the lookout for an application in which to utilize them.when i saw what roy was doing the light came on:laugh: .

roy,if you can imagine the mounts you showed that z1e sells we would mill some billet ones out like those, except these would have tabs out the front and rear to drill holes through to bolt the mounts down.and could also have a series of threaded holes spaced apart to use to lower the bike with.just a thought.

leon

skiatook,oklahoma 1980 z1r,1978 kz 1000 z1r x 3,

1976 kz 900 x 3

i make what i can,and save the rest!

billybiltit.blogspot.com/

www.kzrider.com/forum/5-chassis/325862-triple-tree-custom-work

kzrider.com/forum/5-chassis/294594-frame-bracing?limitstart=0

1976 kz 900 x 3

i make what i can,and save the rest!

billybiltit.blogspot.com/

www.kzrider.com/forum/5-chassis/325862-triple-tree-custom-work

kzrider.com/forum/5-chassis/294594-frame-bracing?limitstart=0

Please Log in or Create an account to join the conversation.

- RoyNor

-

Topic Author

Topic Author

- Offline

- User

-

Registered

- Posts: 359

- Thanks: 1

Re: Z1000R and Z1000J - Lots of pics, and Gun-Kote oven baked paint.

22 Jan 2009 09:41

I am glad the light came on Leon!

I think the solution using nutserts is really nice, and it looks a little bit more special like than welding!

And as you say, its possible to adjust the height.

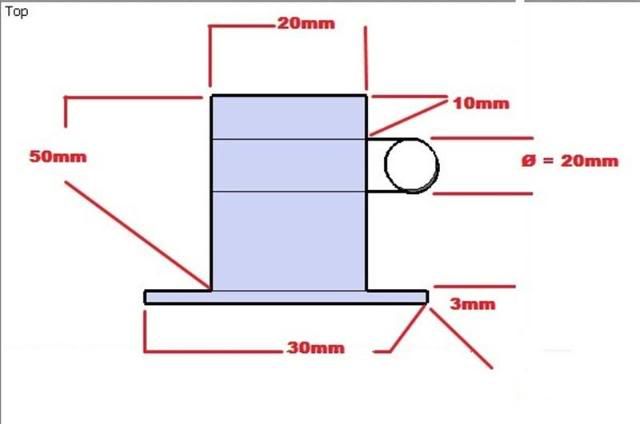

OK, here is what I think.

I dont know the exact thickness that is possible to use, so I put it to 3mm on the drawing.

The machinists opinion is the last word. :lol:

And the plan is using this bushing.

I think the solution using nutserts is really nice, and it looks a little bit more special like than welding!

And as you say, its possible to adjust the height.

OK, here is what I think.

I dont know the exact thickness that is possible to use, so I put it to 3mm on the drawing.

The machinists opinion is the last word. :lol:

And the plan is using this bushing.

Please Log in or Create an account to join the conversation.

- 531blackbanshee

-

- Offline

- Vendor

-

Vendors

- Posts: 7444

- Thanks: 796

Re: Z1000R and Z1000J - Lots of pics, and Gun-Kote oven baked paint.

22 Jan 2009 11:53

roy,

we are on the same page there buddy.

i did not know that you we're also a draftsman,i thought carpenters could only read to about 6mm or 1/4 inch in the usa:laugh: .

i have the 8mm nutserts here at work they cost me $1.27 ea.

using two per end i think that would be a good size to use.providing we have enough width across the tubing for two holes and enough meat to be safe.

nice picture btw.

leon

we are on the same page there buddy.

i did not know that you we're also a draftsman,i thought carpenters could only read to about 6mm or 1/4 inch in the usa:laugh: .

i have the 8mm nutserts here at work they cost me $1.27 ea.

using two per end i think that would be a good size to use.providing we have enough width across the tubing for two holes and enough meat to be safe.

nice picture btw.

leon

skiatook,oklahoma 1980 z1r,1978 kz 1000 z1r x 3,

1976 kz 900 x 3

i make what i can,and save the rest!

billybiltit.blogspot.com/

www.kzrider.com/forum/5-chassis/325862-triple-tree-custom-work

kzrider.com/forum/5-chassis/294594-frame-bracing?limitstart=0

1976 kz 900 x 3

i make what i can,and save the rest!

billybiltit.blogspot.com/

www.kzrider.com/forum/5-chassis/325862-triple-tree-custom-work

kzrider.com/forum/5-chassis/294594-frame-bracing?limitstart=0

Please Log in or Create an account to join the conversation.

- RoyNor

-

Topic Author

Topic Author

- Offline

- User

-

Registered

- Posts: 359

- Thanks: 1

Re: Z1000R and Z1000J - Lots of pics, and Gun-Kote oven baked paint.

22 Jan 2009 13:02

Hehe, My buddy Birger says the same, he believe I cant read measurements if its under 5mm, but he s a thin sheet metal worker. That bastard.

:evil:

The meat in the swing is 3mm thickness, and if I avoid those holes that are in the end, one each leg, where this is gonna be bolted, than its gonna be fine? Huh...

The meat in the swing is 3mm thickness, and if I avoid those holes that are in the end, one each leg, where this is gonna be bolted, than its gonna be fine? Huh...

Please Log in or Create an account to join the conversation.

- 531blackbanshee

-

- Offline

- Vendor

-

Vendors

- Posts: 7444

- Thanks: 796

Re: Z1000R and Z1000J - Lots of pics, and Gun-Kote oven baked paint.

22 Jan 2009 13:31

what size does that hole measure roy?these nutserts i have here need a hole dia of .385 .it almost looks like that hole could be used for one corner of the mount.

skiatook,oklahoma 1980 z1r,1978 kz 1000 z1r x 3,

1976 kz 900 x 3

i make what i can,and save the rest!

billybiltit.blogspot.com/

www.kzrider.com/forum/5-chassis/325862-triple-tree-custom-work

kzrider.com/forum/5-chassis/294594-frame-bracing?limitstart=0

1976 kz 900 x 3

i make what i can,and save the rest!

billybiltit.blogspot.com/

www.kzrider.com/forum/5-chassis/325862-triple-tree-custom-work

kzrider.com/forum/5-chassis/294594-frame-bracing?limitstart=0

Please Log in or Create an account to join the conversation.

Moderators: Street Fighter LTD