Saving a 1980 750 twin.

- 80B4

-

- Offline

- User

-

Registered

- Posts: 447

- Thanks: 105

Please Log in or Create an account to join the conversation.

- GPzMOD750

-

- Offline

- User

-

Registered

- Posts: 1365

- Thanks: 148

Re: Saving a 1980 750 twin.

07 May 2016 09:01 - 07 May 2016 09:0280B4 wrote: I have a ProtoTrak controler on the mill that I use.And I am having a MachMotion 3 axis control installed on my new to me Acer mill. I've been using systems like these for 25 years and they eliminate using a rotary table 99% of the time. I'll post some process photos the next time I make a triple clamp.

I'm a manual guy just getting in to NC/CNC. We have 3 Mach Motion controllers where I work. From what I've seen of the guys using them they have been a real PIA as compared to the Centroid and the old Servo systems that we also have. I know that the Mach Motion is more affordable but it comes at a price elsewhere. They are great for the home 3 axis machinist but for a commercial, even light production environment they can cause some headaches. Yay for the tight-fisted bean counters in the front office!

Keep up using manual equipment Doc, even if it's just a hobby. They are great skills to have that are fast dying in the industry that aren't becoming as useless as once thought. They are quickly learning the error of their ways and are almost too late in correcting the situation. I'm getting more and more calls and emails from companies and recruiters theses days.

Last edit: 07 May 2016 09:02 by GPzMOD750.

Please Log in or Create an account to join the conversation.

- DoctoRot

-

Topic Author

Topic Author

- Offline

- Sustaining Member

-

Registered

- Oh, the usual... I bowl, I drive around...

- Posts: 2605

- Thanks: 766

Re: Saving a 1980 750 twin.

07 May 2016 12:01

Those are super nice Jon. the eccentric bar mount is a nice touch. I would like to see the fixture for that, if you got a photo.

The following user(s) said Thank You: 80B4

Please Log in or Create an account to join the conversation.

- 80B4

-

- Offline

- User

-

Registered

- Posts: 447

- Thanks: 105

Re: Saving a 1980 750 twin.

07 May 2016 22:46

I'm sure I still have it. I'm going to the shop on Monday, I'll photo it then.

Thanks for the compliment.

Thanks for the compliment.

1980B4 1000

1978 Z1R

1978 B3 750

1978 Z1R

1978 B3 750

Please Log in or Create an account to join the conversation.

- 531blackbanshee

-

- Offline

- Vendor

-

Vendors

- Posts: 7444

- Thanks: 796

Re: Saving a 1980 750 twin.

09 May 2016 07:47

i use an

www.amazon.com/INDICOL-Universal-Holder-...iamter/dp/B0006J3XKO

to hold a

www.use-enco.com/1/1/66240-52-562-778-fo...test-indicators.html

for most of my setup on the mill.

but different machined points and plugs get used for quick and dirty stuff.

nice work on the triples 80b4.

leon

www.amazon.com/INDICOL-Universal-Holder-...iamter/dp/B0006J3XKO

to hold a

www.use-enco.com/1/1/66240-52-562-778-fo...test-indicators.html

for most of my setup on the mill.

but different machined points and plugs get used for quick and dirty stuff.

nice work on the triples 80b4.

leon

skiatook,oklahoma 1980 z1r,1978 kz 1000 z1r x 3,

1976 kz 900 x 3

i make what i can,and save the rest!

billybiltit.blogspot.com/

www.kzrider.com/forum/5-chassis/325862-triple-tree-custom-work

kzrider.com/forum/5-chassis/294594-frame-bracing?limitstart=0

1976 kz 900 x 3

i make what i can,and save the rest!

billybiltit.blogspot.com/

www.kzrider.com/forum/5-chassis/325862-triple-tree-custom-work

kzrider.com/forum/5-chassis/294594-frame-bracing?limitstart=0

The following user(s) said Thank You: 80B4

Please Log in or Create an account to join the conversation.

- DoctoRot

-

Topic Author

Topic Author

- Offline

- Sustaining Member

-

Registered

- Oh, the usual... I bowl, I drive around...

- Posts: 2605

- Thanks: 766

Re: Saving a 1980 750 twin.

26 May 2016 16:58

I'm back in Seattle for the summer, my friend has been gracious enough to let me use his shop and even made me a key so I can come and go as I please. What a guy! I made a list of materials and parts I need to buy and should start fabrication on the headers next week. My buddy has a "rose bud" torch so I'm going to give the sand filled tube bending a try, a-la-Yoshimura. I'll attempt it in mild steel first and if that goes well I will try it in stainless. I mocked it up with some tube he had laying around. I don't think they'll be quite as swoopy as this.

The following user(s) said Thank You: 750Kruzer

Please Log in or Create an account to join the conversation.

- ThatGPzGuy

-

- Offline

- Sustaining Member

-

Registered

- More Sparky than Speed Racer

- Posts: 1524

- Thanks: 402

Re: Saving a 1980 750 twin.

10 Jun 2016 18:01

Really liking this build. Nice work.

As far as the exhaust you may want to check out stock XS650 headers vs. the aftermarket. The stock headers are on the "swoopy" side while the aftermarket replacements follow the lines of the frame and are more squared off. A much better looking pipe in my opinion.

As far as the exhaust you may want to check out stock XS650 headers vs. the aftermarket. The stock headers are on the "swoopy" side while the aftermarket replacements follow the lines of the frame and are more squared off. A much better looking pipe in my opinion.

Jim

North GA

2016 Yamaha FJR1300ES

1982 GPz750 R1

1974 Kawasaki H1

1976 Kawasaki KZ400

1979 Yamaha XS650 cafe'

2001 KZ1000P (sold)

2001 Yamaha YZ426

1981 Honda XR200 stroked in an '89 CR125 chassis

1965 Mustang

1967 Triumph GT6

1976 Bronco

"If you didn't build it, it's not really yours"

North GA

2016 Yamaha FJR1300ES

1982 GPz750 R1

1974 Kawasaki H1

1976 Kawasaki KZ400

1979 Yamaha XS650 cafe'

2001 KZ1000P (sold)

2001 Yamaha YZ426

1981 Honda XR200 stroked in an '89 CR125 chassis

1965 Mustang

1967 Triumph GT6

1976 Bronco

"If you didn't build it, it's not really yours"

Please Log in or Create an account to join the conversation.

- DoctoRot

-

Topic Author

Topic Author

- Offline

- Sustaining Member

-

Registered

- Oh, the usual... I bowl, I drive around...

- Posts: 2605

- Thanks: 766

Re: Saving a 1980 750 twin.

16 Jun 2016 01:35

Well i got distracted for 12 days, I had the opportunity to do an impromptu back-country hike in the Sawtooth Wilderness, so I rode out there and took the long way back. There were a lot of thunderstorms and even rode through some hail. Most of these photos are in Idaho and Central Oregon. I camped in national forests along the way, dirt-bagging it. good times.

Please Log in or Create an account to join the conversation.

- DoctoRot

-

Topic Author

Topic Author

- Offline

- Sustaining Member

-

Registered

- Oh, the usual... I bowl, I drive around...

- Posts: 2605

- Thanks: 766

Re: Saving a 1980 750 twin.

16 Jun 2016 01:36 - 16 Jun 2016 01:52

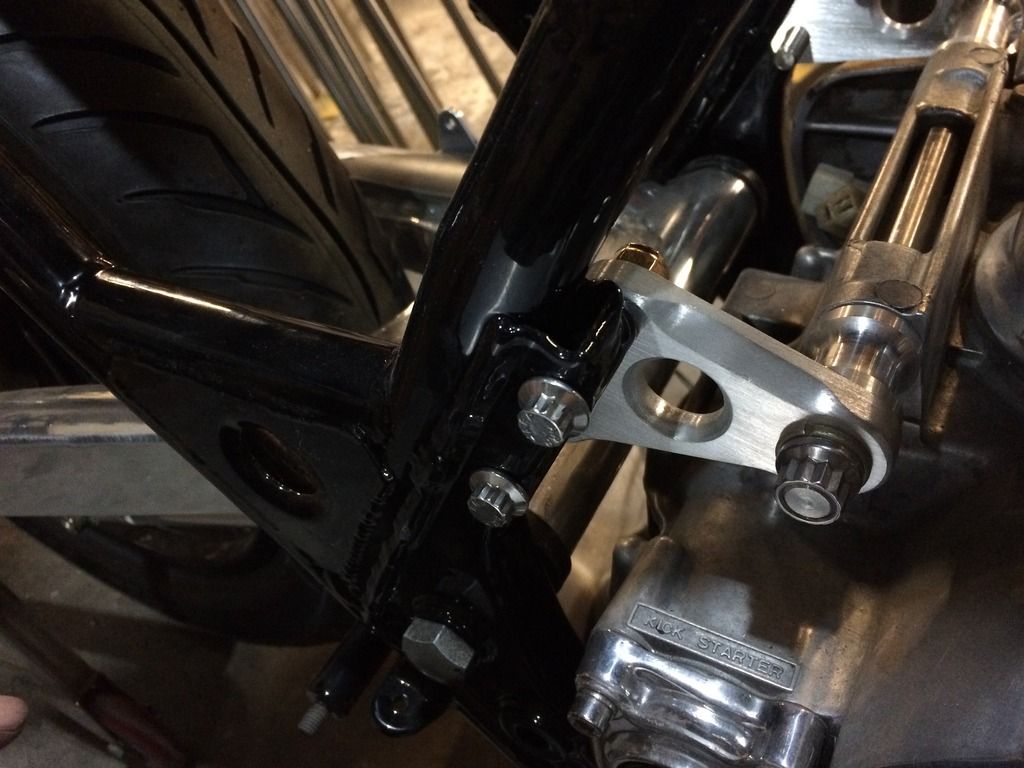

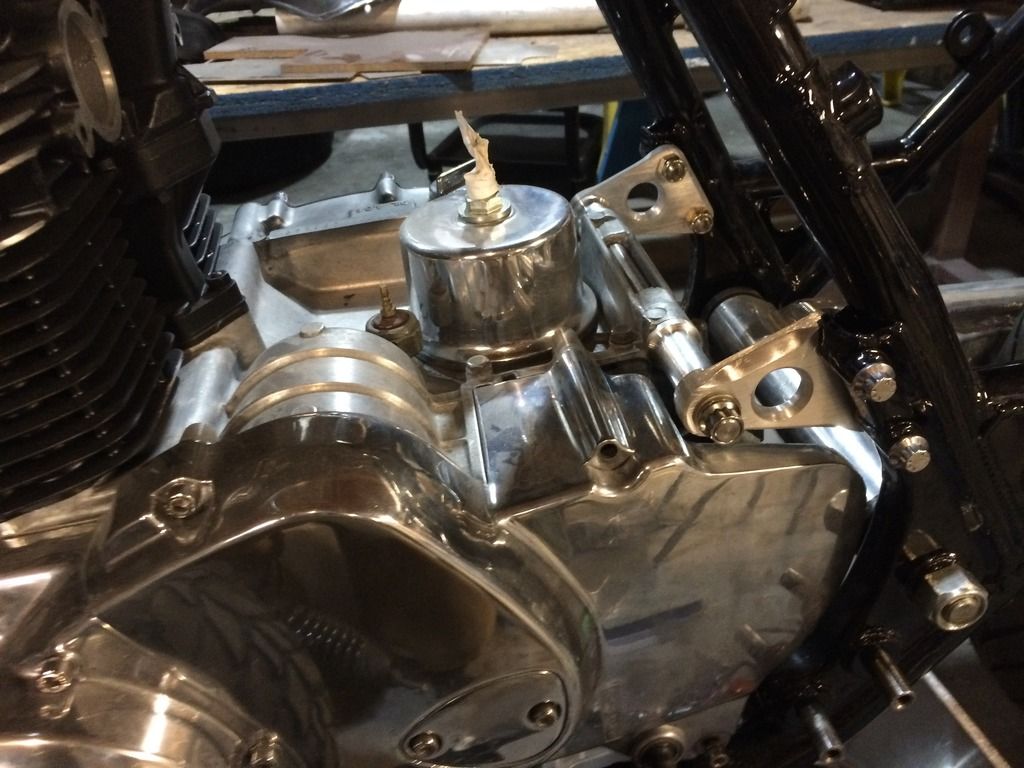

After getting back from the trip I did manage to get some work in on the bike. I made the plates for the close tolerance motor mounts and I chamfered them to match the exhaust collars. I also fit the ring I turned for the tach in the headlight bucket and glued it in with some JB weld.

I finally got everything setup to do some sand bending. I already had some 1.5" tube with .095 wall so i tried it with that. for the final i will use 1.5" .065 wall. I don't know how much of a difference there will be in bending them with heat. The smaller kinked radius was the first attempt, the second attempt got a little crushed as well but it was a big improvement. The sand I used was damp when i packed it in there (there were vent holes) and im wondering if that perhaps the loss of water mass as vapour (which there was quite of bit of) allowed the sand to be looser. I'm also going to try welding a nut on the ends and using some all-thread to form a "packer" once it is welded shut. gonna give it another go this weekend hopefully.

any suggestions?

I finally got everything setup to do some sand bending. I already had some 1.5" tube with .095 wall so i tried it with that. for the final i will use 1.5" .065 wall. I don't know how much of a difference there will be in bending them with heat. The smaller kinked radius was the first attempt, the second attempt got a little crushed as well but it was a big improvement. The sand I used was damp when i packed it in there (there were vent holes) and im wondering if that perhaps the loss of water mass as vapour (which there was quite of bit of) allowed the sand to be looser. I'm also going to try welding a nut on the ends and using some all-thread to form a "packer" once it is welded shut. gonna give it another go this weekend hopefully.

any suggestions?

Last edit: 16 Jun 2016 01:52 by DoctoRot.

The following user(s) said Thank You: 80B4

Please Log in or Create an account to join the conversation.

- loudhvx

-

- Offline

- KZr Legend

-

Registered

- Posts: 10863

- Thanks: 1622

Re: Saving a 1980 750 twin.

16 Jun 2016 18:28 - 16 Jun 2016 18:30

Great photos of a beautiful area! We drove (rental cage) out of Yellowstone, through Jackson, down to Twin Falls Idaho, a week ago... probably missed ya by 100 miles. It's really difficult to capture, on camera, what you see in person out there.

The clamp and gauge cluster is looking great...not to mention the other art-gallery bits!

The clamp and gauge cluster is looking great...not to mention the other art-gallery bits!

1981 KZ550 D1 gpz.

Kz550 valve train warning.

Other links.

Kz550 valve train warning.

Other links.

Last edit: 16 Jun 2016 18:30 by loudhvx.

Please Log in or Create an account to join the conversation.

- DoctoRot

-

Topic Author

Topic Author

- Offline

- Sustaining Member

-

Registered

- Oh, the usual... I bowl, I drive around...

- Posts: 2605

- Thanks: 766

Re: Saving a 1980 750 twin.

24 Jun 2016 20:43

Thanks for the kind words.

I got some 1.5" .065" wall tube. With the dry sand I could pack it much better. This was the second attempt but I ran out of O2. I think with a bit more practice I can get it pretty nice. The tight radius only crushed .17" I'm gonna try heating it a bit differently next time and see what happens.

I got some 1.5" .065" wall tube. With the dry sand I could pack it much better. This was the second attempt but I ran out of O2. I think with a bit more practice I can get it pretty nice. The tight radius only crushed .17" I'm gonna try heating it a bit differently next time and see what happens.

Please Log in or Create an account to join the conversation.

- SWest

-

- Offline

- Sustaining Member

-

Registered

- 10 22 2014

- Posts: 23611

- Thanks: 2985

Re: Saving a 1980 750 twin.

24 Jun 2016 20:50

Saw this a long time ago.

Steve

Steve

Z1b1000 1975 Z1b

kzrider.com/forum/11-projects/598262-kz-...-will-it-live#672882

kzrider.com/forum/2-engine/597654-poser?start=240#704229

kzrider.com/forum/11-projects/598262-kz-...-will-it-live#672882

kzrider.com/forum/2-engine/597654-poser?start=240#704229

Please Log in or Create an account to join the conversation.

Moderators: Street Fighter LTD