GPZ 750 heat flatness

- Poudrette

-

Topic Author

- Offline

- User

- Posts: 6

- Thanks: 0

GPZ 750 heat flatness

29 Jun 2016 20:39

Tore down the engine to change piston rings and put a calibrated straight edge from cyl 1 to cyl 4, measuring flatness around each combustion chamber, on the head side of course. Finding +- 1 mil flatness,. Wondering if this really warrants a machining correction

thx for your opinion

Sylvain

thx for your opinion

Sylvain

Please Log in or Create an account to join the conversation.

- zed1015

-

- Offline

- User

- Posts: 3128

- Thanks: 1735

Re: GPZ 750 heat flatness

30 Jun 2016 04:58

If it wasn't leaking, leave it alone.

AIR CORRECTOR JETS FOR VM CARBS AND ETHANOL RESISTANT VITON CHOKE PLUNGER SEAL REPLACMENT FOR ALL CLASSIC AND MODERN MOTORCYCLE CARBURETTORS

www.kzrider.com/23-for-sale/611992-air-c...lide-mikunis?start=0

www.kzrider.com/23-for-sale/611992-air-c...lide-mikunis?start=0

Please Log in or Create an account to join the conversation.

- Nessism

-

- Offline

- Sustaining Member

- Posts: 7664

- Thanks: 3034

Re: GPZ 750 heat flatness

30 Jun 2016 07:07

Sorry, I don't know what a "mil" means. The service limit is .05mm.

I've read posts before from Jay at APE that the head will flatten when you tighten it down. Skimming the head flat can result in the cam bores being jacked up afterwards since they were parallel when leaving the factory.

I've read posts before from Jay at APE that the head will flatten when you tighten it down. Skimming the head flat can result in the cam bores being jacked up afterwards since they were parallel when leaving the factory.

Ed

Carb O-ring Kits : www.kzrider.com/forum/3-carburetor/61807...-o-ring-kits?start=0

www.kzrider.com/forum/faq-wiki/618026-new-owner-things-to-know

1981 KZ750E2

www.kzrider.com/forum/11-projects/604901...z750e-project-thread

Carb O-ring Kits : www.kzrider.com/forum/3-carburetor/61807...-o-ring-kits?start=0

www.kzrider.com/forum/faq-wiki/618026-new-owner-things-to-know

1981 KZ750E2

www.kzrider.com/forum/11-projects/604901...z750e-project-thread

Please Log in or Create an account to join the conversation.

- Poudrette

-

Topic Author

- Offline

- User

- Posts: 6

- Thanks: 0

Re: GPZ 750 heat flatness

04 Jul 2016 17:43

Thanks it was definitely not leaking on the outside but might have had something funny (leaking towards the camchain cavity perhaps) cause orininally the bow at the middle was 6 mils (0.006 inch) and IO always had a start compression issue with this bike.. I put a picture of the head after diaseembly and it seems to me that htere is a lot of RTV looking thick enough near several cyclinders.

I simplified the question to provide the present condition with about 1 mil (0.001 inch) and my question accordingly. Thanks for the answers. Hopefully this will be flat enough if the service limit is 0.05 mm, i.e. 40 mils / mm * 0.05 = 2 mils = 0.002 inch.

I actually went from 6 to 1 mil by straightening it in an old kitchen oven (outside haha the stink) on a flat milled, threaded steel plate after removing the valve springs. Bolted it down with 3/8 bolts and yes it did flatten down to the plate quite well even cold. I saw this on youtube and it made lots of sense, why mill and keep the cam bearings misaligned when it can be strightened instead. I made sure to read the head temperature with a small BBQ meat thermometer stuck deep in the sparkplug hole. Anyway after two cycles at 400 deg F for 10 hours/cycle (and playing a bit with shims cause there is some sort of springback at dassembly) it is now freestate flat to 1-2 mils.

Thanks for your help again and good luck to me for the next steps. I need it cause I ve never done this before. I measured the cyclinder bores (nominal) and I just changed my o rings and broke the finish of the cylinders with (China made) stones on a drill attachment. I see very light vertical scuffing that stays after honing for about 60 seconds with oil, I think this will ok and am getting ready to try out the ring compressor sleeve gizmos. Any hints are welcome please !

By the way, I see in the Clymer manual; that there are 8 plugs at the bottom of the cylinder block, looks like against the engine case. ANyone know what these are for ? There s no oil passage there or anything I think.

I simplified the question to provide the present condition with about 1 mil (0.001 inch) and my question accordingly. Thanks for the answers. Hopefully this will be flat enough if the service limit is 0.05 mm, i.e. 40 mils / mm * 0.05 = 2 mils = 0.002 inch.

I actually went from 6 to 1 mil by straightening it in an old kitchen oven (outside haha the stink) on a flat milled, threaded steel plate after removing the valve springs. Bolted it down with 3/8 bolts and yes it did flatten down to the plate quite well even cold. I saw this on youtube and it made lots of sense, why mill and keep the cam bearings misaligned when it can be strightened instead. I made sure to read the head temperature with a small BBQ meat thermometer stuck deep in the sparkplug hole. Anyway after two cycles at 400 deg F for 10 hours/cycle (and playing a bit with shims cause there is some sort of springback at dassembly) it is now freestate flat to 1-2 mils.

Thanks for your help again and good luck to me for the next steps. I need it cause I ve never done this before. I measured the cyclinder bores (nominal) and I just changed my o rings and broke the finish of the cylinders with (China made) stones on a drill attachment. I see very light vertical scuffing that stays after honing for about 60 seconds with oil, I think this will ok and am getting ready to try out the ring compressor sleeve gizmos. Any hints are welcome please !

By the way, I see in the Clymer manual; that there are 8 plugs at the bottom of the cylinder block, looks like against the engine case. ANyone know what these are for ? There s no oil passage there or anything I think.

Attachments:

Please Log in or Create an account to join the conversation.

- SWest

-

- Offline

- Sustaining Member

- 10 22 2014

- Posts: 23331

- Thanks: 2875

Re: GPZ 750 heat flatness

04 Jul 2016 17:56

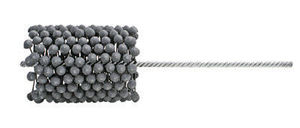

You need a good 45* cross hatch in the cylinders for the rings to seat. Use a bottle brush if they are straight.

Steve

Steve

Z1b1000 1975 Z1b

kzrider.com/forum/11-projects/598262-kz-...-will-it-live#672882

kzrider.com/forum/2-engine/597654-poser?start=240#704229

kzrider.com/forum/11-projects/598262-kz-...-will-it-live#672882

kzrider.com/forum/2-engine/597654-poser?start=240#704229

Please Log in or Create an account to join the conversation.

- MadShad

-

- Offline

- User

- Posts: 232

- Thanks: 8

Re: GPZ 750 heat flatness

04 Jul 2016 20:59Poudrette wrote: Thanks it was definitely not leaking on the outside but might have had something funny (leaking towards the camchain cavity perhaps) cause orininally the bow at the middle was 6 mils (0.006 inch) and IO always had a start compression issue with this bike.. I put a picture of the head after diaseembly and it seems to me that htere is a lot of RTV looking thick enough near several cyclinders.

Thanks for your help again and good luck to me for the next steps. I need it cause I ve never done this before. I measured the cyclinder bores (nominal) and I just changed my o rings and broke the finish of the cylinders with (China made) stones on a drill attachment. I see very light vertical scuffing that stays after honing for about 60 seconds with oil, I think this will ok and am getting ready to try out the ring compressor sleeve gizmos. Any hints are welcome please !

By the way, I see in the Clymer manual; that there are 8 plugs at the bottom of the cylinder block, looks like against the engine case. ANyone know what these are for ? There s no oil passage there or anything I think.

That rtv is a mess, sorry you had to clean that up. I recently had some cylinders honed by somebody who knows what they are doing, some of my vertical lines remained, but were faint.

Those rubber plugs at the bottom of the cylinder blocks do not serve any sealing purpose, vibration perhaps?

Shelbyville, Indiana. '80 KZ1000

No more of that talk or I'll put the leeches on you, understand?

No more of that talk or I'll put the leeches on you, understand?

Please Log in or Create an account to join the conversation.

- SWest

-

- Offline

- Sustaining Member

- 10 22 2014

- Posts: 23331

- Thanks: 2875

Re: GPZ 750 heat flatness

04 Jul 2016 21:23

I took mine out 40 years ago, now I have to clean them out. :dry:

Steve

Steve

Z1b1000 1975 Z1b

kzrider.com/forum/11-projects/598262-kz-...-will-it-live#672882

kzrider.com/forum/2-engine/597654-poser?start=240#704229

kzrider.com/forum/11-projects/598262-kz-...-will-it-live#672882

kzrider.com/forum/2-engine/597654-poser?start=240#704229

Please Log in or Create an account to join the conversation.

- missionkz

-

- Offline

- Sustaining Member

- Posts: 1622

- Thanks: 184

Re: GPZ 750 heat flatness

04 Jul 2016 21:26 - 04 Jul 2016 21:30I think the rubber plugs are supposed to dampen cylinder ringing.MadShad wrote:Poudrette wrote: Thanks it was definitely not leaking on the outside but might have had something funny (leaking towards the camchain cavity perhaps) cause orininally the bow at the middle was 6 mils (0.006 inch) and IO always had a start compression issue with this bike.. I put a picture of the head after diaseembly and it seems to me that htere is a lot of RTV looking thick enough near several cyclinders.

Thanks for youdaasr help again and good luck to me for the next steps. I need it cause I ve never done this before. I measured the cyclinder bores (nominal) and I just changed my o rings and broke the finish of the cylinders with (China made) stones on a drill attachment. I see very light vertical scuffing that stays after honing for about 60 seconds with oil, I think this will ok and am getting ready to try out the ring compressor sleeve gizmos. Any hints are welcome please !

By the way, I see in the Clymer manual; that there are 8 plugs at the bottom of the cylinder block, looks like against the engine case. ANyone know what these are for ? There s no oil passage there or anything I think.

That rtv is a mess, sorry you had to clean that up. I recently had some cylinders honed by somebody who knows what they are doing, some of my vertical lines remained, but were faint.

Those rubber plugs at the bottom of the cylinder blocks do not serve any sealing purpose, vibration perhaps?

Looks like cylinder #1 has worn rings and or valve guide seal. Hopefully hone and rings will help but now is also the time to take the valves out and replace all the valve guide seal bonnets.

Bruce

1977 KZ1000A1

2016 Triumph T120 Bonneville

Far North East Metro Denver Colorado

1977 KZ1000A1

2016 Triumph T120 Bonneville

Far North East Metro Denver Colorado

Last edit: 04 Jul 2016 21:30 by missionkz.

Please Log in or Create an account to join the conversation.

- Poudrette

-

Topic Author

- Offline

- User

- Posts: 6

- Thanks: 0

Re: GPZ 750 heat flatness

05 Jul 2016 10:32

I did a test on the valve seats before valve disassembly, (again from youtube video haha) filling the space above with gasoline and seeing if it woul leak through in the combustion chamber between valve and valve seat. After a good while, I did not see a single drop on any of 4 exhaust or 4 inlet valves. Wondering if this is considered a good approach by all here to decide if the seat is good, at least before disassembly. I did check for compression before disassembly with the sponnful of oil in the cylinder and tht why «i decided to change the rings and assume the valves are at least mostly ok. If I understand your feedback properly, you are suggesting to change valve guides to avoi oil going into the combustion chmber when valve open up ?

Kawasaki recommend using a special compound liquid gasket (they even give it a Kawa part number per the Clymer manual) between cylinder base and top of engine case, around the cylinder sleeves. Anyone knows a good substitute or equivalent ? Nothing like it at the auto parts store I believe, all high temp compounds seem to be for flexible joints, not rigid metal to metal joints. Perhaps this is against frettage somehow ? I was surprised to find an all mtal gasket there between engine case and cylinder block, is this usual in your experience ? I managed to get an engin gasket kit for a KZ750 as none were easily available for the GPZ 750, the seller told me that all gaskets woul be the same for the cylinder / head stack but i m not sure anymore.

Wow thak again for your help

Sylvain

Kawasaki recommend using a special compound liquid gasket (they even give it a Kawa part number per the Clymer manual) between cylinder base and top of engine case, around the cylinder sleeves. Anyone knows a good substitute or equivalent ? Nothing like it at the auto parts store I believe, all high temp compounds seem to be for flexible joints, not rigid metal to metal joints. Perhaps this is against frettage somehow ? I was surprised to find an all mtal gasket there between engine case and cylinder block, is this usual in your experience ? I managed to get an engin gasket kit for a KZ750 as none were easily available for the GPZ 750, the seller told me that all gaskets woul be the same for the cylinder / head stack but i m not sure anymore.

Wow thak again for your help

Sylvain

Please Log in or Create an account to join the conversation.

- Poudrette

-

Topic Author

- Offline

- User

- Posts: 6

- Thanks: 0

Re: GPZ 750 heat flatness

05 Jul 2016 10:36

You mean a brush with stiff steel wires of about 3 inch dia ? Soory never heard of bottle brushes, not making wine or beer haha

I ll look on eBay or maybe car parts store ?

cheers

I ll look on eBay or maybe car parts store ?

cheers

Please Log in or Create an account to join the conversation.

- Nessism

-

- Offline

- Sustaining Member

- Posts: 7664

- Thanks: 3034

Re: GPZ 750 heat flatness

05 Jul 2016 11:13Poudrette wrote: I did a test on the valve seats before valve disassembly, (again from youtube video haha) filling the space above with gasoline and seeing if it woul leak through in the combustion chamber between valve and valve seat. After a good while, I did not see a single drop on any of 4 exhaust or 4 inlet valves. Wondering if this is considered a good approach by all here to decide if the seat is good, at least before disassembly. I did check for compression before disassembly with the sponnful of oil in the cylinder and tht why «i decided to change the rings and assume the valves are at least mostly ok. If I understand your feedback properly, you are suggesting to change valve guides to avoi oil going into the combustion chmber when valve open up ?

Kawasaki recommend using a special compound liquid gasket (they even give it a Kawa part number per the Clymer manual) between cylinder base and top of engine case, around the cylinder sleeves. Anyone knows a good substitute or equivalent ? Nothing like it at the auto parts store I believe, all high temp compounds seem to be for flexible joints, not rigid metal to metal joints. Perhaps this is against frettage somehow ? I was surprised to find an all mtal gasket there between engine case and cylinder block, is this usual in your experience ? I managed to get an engin gasket kit for a KZ750 as none were easily available for the GPZ 750, the seller told me that all gaskets woul be the same for the cylinder / head stack but i m not sure anymore.

Wow thak again for your help

Sylvain

That Kawabond stuff is made by Threebond. 1184 is the latest version of the gray sealer. Threebond also makes RTV which works well in the application as well. 1207B is the number for that stuff. I believe Permatex Ultra Gray RTV will work fine as well. As with any RTV you need to use it sparingly for fear of excess splooge out.

Ed

Carb O-ring Kits : www.kzrider.com/forum/3-carburetor/61807...-o-ring-kits?start=0

www.kzrider.com/forum/faq-wiki/618026-new-owner-things-to-know

1981 KZ750E2

www.kzrider.com/forum/11-projects/604901...z750e-project-thread

Carb O-ring Kits : www.kzrider.com/forum/3-carburetor/61807...-o-ring-kits?start=0

www.kzrider.com/forum/faq-wiki/618026-new-owner-things-to-know

1981 KZ750E2

www.kzrider.com/forum/11-projects/604901...z750e-project-thread

The following user(s) said Thank You: Poudrette

Please Log in or Create an account to join the conversation.

- Nessism

-

- Offline

- Sustaining Member

- Posts: 7664

- Thanks: 3034

Re: GPZ 750 heat flatness

05 Jul 2016 11:14Poudrette wrote: You mean a brush with stiff steel wires of about 3 inch dia ? Soory never heard of bottle brushes, not making wine or beer haha

I ll look on eBay or maybe car parts store ?

cheers

www.enginehones.com/

Ed

Carb O-ring Kits : www.kzrider.com/forum/3-carburetor/61807...-o-ring-kits?start=0

www.kzrider.com/forum/faq-wiki/618026-new-owner-things-to-know

1981 KZ750E2

www.kzrider.com/forum/11-projects/604901...z750e-project-thread

Carb O-ring Kits : www.kzrider.com/forum/3-carburetor/61807...-o-ring-kits?start=0

www.kzrider.com/forum/faq-wiki/618026-new-owner-things-to-know

1981 KZ750E2

www.kzrider.com/forum/11-projects/604901...z750e-project-thread

The following user(s) said Thank You: Poudrette

Please Log in or Create an account to join the conversation.