Search Results (Searched for: gs swing arm)

No I have not, but the shaft DOES prevent the side to side motion exactly as stock. The RH roller bearing is the lateral limiting device in the stock ZRX swing arm. It is trapped in a stock ZRX by the RH "top hat" bushing and the LH side sleeve that rides in the needle bearings. All of that is sandwiched between the frame mounts. All the stock ZRX bearings and the LH sleeve is retained and the "top hat" bushing feature for the RH is incorporated into the shaft I designed. Using grade 8 5/8" fine thread bolts to bolt the shaft into the frame holds everything tight and ridged. Mine fits like a glove.

As far as simple, it is one shaft with two bolts. Versus a long bolt, nut, and two individual bushings. So not sure it is more complicated.

Cory

As far as simple, it is one shaft with two bolts. Versus a long bolt, nut, and two individual bushings. So not sure it is more complicated.

Cory

Replied by scubaanders on topic GPZ750R1 -82 Will it be yet an other green Kwack

20 Feb 2016 03:51

I have my bike up in my buddy Erik’s garage (50km away) so there is a lot of things that need to work in order to get work done on the bike, and to make things worse Erik gave his daughter a Hoverboard for X-mas. Guess you can figure out the rest. . :blink: . . . yes there were some serious surgery :S needed to get him back in good working order again and the days we had set of around new years were lost.

Anyhow, we are back at it.

First up, fitting the Zephyr 750 swing arm.

The Gpz750R1 measures 230mm between the studs and the Zephyr 750 swing arm is 234mm, so while I shaved of 2mm on each side Erik milled the Zephyr pivot tube down to 230mm.

Secondly we had to deal with the fact that the swing bolt is 16mm and the id of the Zephyr pivot tube is 20mm. Our fix was to fit a piece of high precision steel tube that by chance had just that od/id inside the pivot tube.

And everything went on the bike like a charm.

In order to secure that the end seals stay in the swingarm, Erik made two spacers of delrin that fits over the studs in the frame and will stop the seals from getting out of the swingarm. (not in the picture)

Next up is fitting the wheels, which means changing the wheel bearings from 20mm id to 17mm to fit the Zephyr wheel axels and centering them in the frame.

Unfortunately we ran in to a little bit of a snag with the front wheel as it turned out that the donor bike, a ZXR400 has 210mm fork spacing and the Zephyr fork only 200mm which put the wheel ca 10mm of to the right. Bummer. :pinch:

/A

Anyhow, we are back at it.

First up, fitting the Zephyr 750 swing arm.

The Gpz750R1 measures 230mm between the studs and the Zephyr 750 swing arm is 234mm, so while I shaved of 2mm on each side Erik milled the Zephyr pivot tube down to 230mm.

Secondly we had to deal with the fact that the swing bolt is 16mm and the id of the Zephyr pivot tube is 20mm. Our fix was to fit a piece of high precision steel tube that by chance had just that od/id inside the pivot tube.

And everything went on the bike like a charm.

In order to secure that the end seals stay in the swingarm, Erik made two spacers of delrin that fits over the studs in the frame and will stop the seals from getting out of the swingarm. (not in the picture)

Next up is fitting the wheels, which means changing the wheel bearings from 20mm id to 17mm to fit the Zephyr wheel axels and centering them in the frame.

Unfortunately we ran in to a little bit of a snag with the front wheel as it turned out that the donor bike, a ZXR400 has 210mm fork spacing and the Zephyr fork only 200mm which put the wheel ca 10mm of to the right. Bummer. :pinch:

/A

Replied by rstnick on topic kz650 swing arm sleeve hard to get in?

14 Feb 2016 06:35 - 14 Feb 2016 06:37

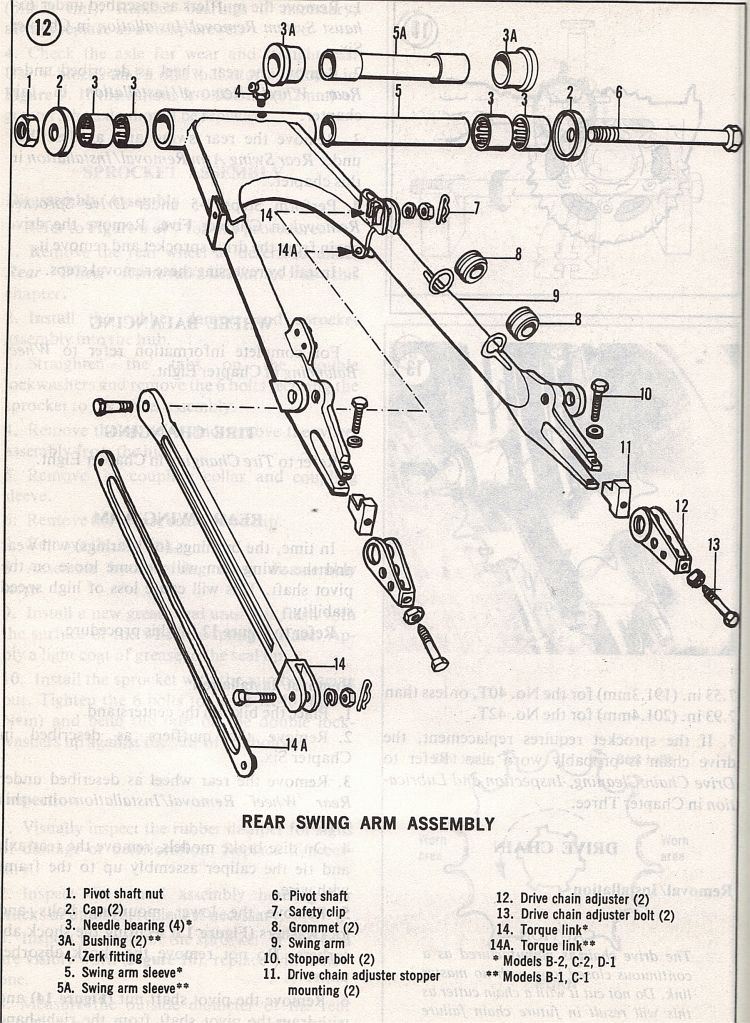

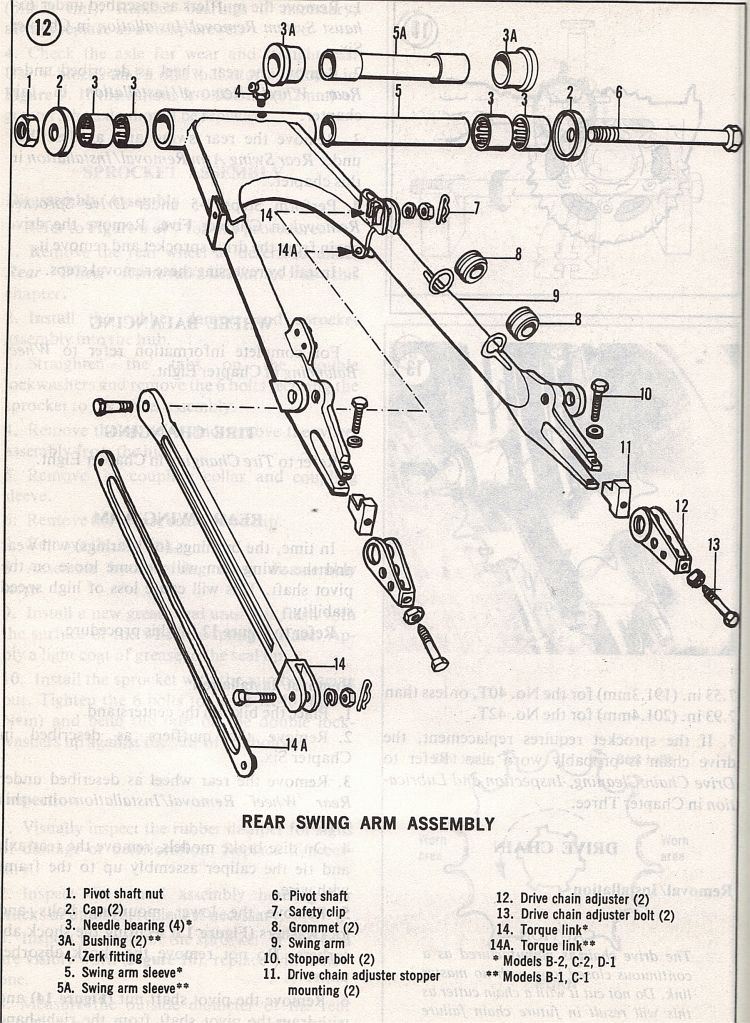

As KZB2 650 stated, with the mags on the bike, you must have a C (or D) model swingarm.

I believe the B models use the same bearings though.

There are different sleeves for the models that use bushings, and those that use bearings.

Parts 5 and 5A in the diagram:

The swingarm, when installed, should move easily.

I believe the B models use the same bearings though.

There are different sleeves for the models that use bushings, and those that use bearings.

Parts 5 and 5A in the diagram:

The swingarm, when installed, should move easily.

Replied by PLUMMEN on topic kz650 swing arm sleeve hard to get in?

13 Feb 2016 22:00

Some swingarms have gone years without seeing a grease gun,When the old bushings or bearings get beaten into submission and stop moving it can do bad things like warp the sleeve or pivot tube.

Thats why I like to spend a few bucks and have the pivot tube checked/line honed by a machine shop if theres any doubt in it being straight,Sometimes its easier to just buy a flee bay swingarm and start over.

Or you could check kz650.info to see if somebody has spare thats in better shape.

Thats why I like to spend a few bucks and have the pivot tube checked/line honed by a machine shop if theres any doubt in it being straight,Sometimes its easier to just buy a flee bay swingarm and start over.

Or you could check kz650.info to see if somebody has spare thats in better shape.

Replied by blink543 on topic kz650 swing arm sleeve hard to get in?

12 Feb 2016 14:31scubaanders wrote: No the swingarm is not supposed to get stuck when you tighten the swing arm bolt. There can be a bit of resistance, but it’s not supposed to get stuck.

But let’s start from the beginning.

1. You cleaned out the swing arm tube from all old grease and dirt and there was no damage done inside the tube.

2. You made sure the pivot tube was not pitted or damaged in any other way. No fragments of steel sticking out, and you made sure it was soft as a toddler but.

3. You checked the pivot tube is strait, you can check this by rolling the tube over a perfectly flat surface. If the tube is bent, replace it.

4. You made sure the new bearings slid on the pivot tube just fine and you could rotate the bearings without any problems.

5. You fitted the bearings into the swingarm without use of any brute force.

6. Greased everything up.

7. Slid the pivottube in. (wiggle, turn, wiggle) and you made sure you could still rotate the pivottube within the swingarm with the use of your thumbs.

8. Fitted the outer dust caps. (They are there to keep the grease in and dirt out).

9. Fitted the swingarm in to the frame.

10. Put the swingarm bolt through (The swingarm bolts is not to always 100% strait, but it’s usually no biggie. You can check the same way as with the pivot tube.

11. You tighten the swingarm bolt, thigh but let’s not overdo it.

12. The swing arm can stay in an up position, but you should be able to move it up and down without excess force.

If it still doesn’t work, post some pictures of all parts for me and Steve to diagnose.

Except for that I can only think of an old Swedish saying that my buddy’s mechanical engineering teacher always said.

- Man kan inte köra häst kuk i kattfitta.

Google translate will be of help to understand it.

/A

Well I can tighten the bolt and I can move the swing arm up and down but not effortlessly either as stated elsewhere. I know for a fact tho that the bearings went on the sleeve fine but the sleeve didn't go in easily and I know the sleeve won't turn inside the swing arm either. I greased the shit out of the swing arm. I connected a grease gun to the zirk fitting and filled it with grease.

Replied by scubaanders on topic kz650 swing arm sleeve hard to get in?

12 Feb 2016 09:40

No the swingarm is not supposed to get stuck when you tighten the swing arm bolt. There can be a bit of resistance, but it’s not supposed to get stuck.

But let’s start from the beginning.

1. You cleaned out the swing arm tube from all old grease and dirt and there was no damage done inside the tube.

2. You made sure the pivot tube was not pitted or damaged in any other way. No fragments of steel sticking out, and you made sure it was soft as a toddler but.

3. You checked the pivot tube is strait, you can check this by rolling the tube over a perfectly flat surface. If the tube is bent, replace it.

4. You made sure the new bearings slid on the pivot tube just fine and you could rotate the bearings without any problems.

5. You fitted the bearings into the swingarm without use of any brute force.

6. Greased everything up.

7. Slid the pivottube in. (wiggle, turn, wiggle) and you made sure you could still rotate the pivottube within the swingarm with the use of your thumbs.

8. Fitted the outer dust caps. (They are there to keep the grease in and dirt out).

9. Fitted the swingarm in to the frame.

10. Put the swingarm bolt through (The swingarm bolts is not to always 100% strait, but it’s usually no biggie. You can check the same way as with the pivot tube.

11. You tighten the swingarm bolt, thigh but let’s not overdo it.

12. The swing arm can stay in an up position, but you should be able to move it up and down without excess force.

If it still doesn’t work, post some pictures of all parts for me and Steve to diagnose.

Except for that I can only think of an old Swedish saying that my buddy’s mechanical engineering teacher always said.

- Man kan inte köra häst kuk i kattfitta.

Google translate will be of help to understand it.

/A

But let’s start from the beginning.

1. You cleaned out the swing arm tube from all old grease and dirt and there was no damage done inside the tube.

2. You made sure the pivot tube was not pitted or damaged in any other way. No fragments of steel sticking out, and you made sure it was soft as a toddler but.

3. You checked the pivot tube is strait, you can check this by rolling the tube over a perfectly flat surface. If the tube is bent, replace it.

4. You made sure the new bearings slid on the pivot tube just fine and you could rotate the bearings without any problems.

5. You fitted the bearings into the swingarm without use of any brute force.

6. Greased everything up.

7. Slid the pivottube in. (wiggle, turn, wiggle) and you made sure you could still rotate the pivottube within the swingarm with the use of your thumbs.

8. Fitted the outer dust caps. (They are there to keep the grease in and dirt out).

9. Fitted the swingarm in to the frame.

10. Put the swingarm bolt through (The swingarm bolts is not to always 100% strait, but it’s usually no biggie. You can check the same way as with the pivot tube.

11. You tighten the swingarm bolt, thigh but let’s not overdo it.

12. The swing arm can stay in an up position, but you should be able to move it up and down without excess force.

If it still doesn’t work, post some pictures of all parts for me and Steve to diagnose.

Except for that I can only think of an old Swedish saying that my buddy’s mechanical engineering teacher always said.

- Man kan inte köra häst kuk i kattfitta.

Google translate will be of help to understand it.

/A

Replied by blink543 on topic kz650 swing arm sleeve hard to get in?

11 Feb 2016 11:20swest wrote: Sounds like it. Spacer too long? Does the pivot bolt go through smoothly?

Steve

The bolt is not the problem it's the sleeve I think. It won't rotate in the swing arm around the bearings. If I tighten down the pivot bolt then lift up the swing arm, it'll stay up. My understanding is it's supposed to move freely

Replied by blink543 on topic kz650 swing arm sleeve hard to get in?

11 Feb 2016 10:14

Well I bought new bearings again and gently put them in by using a threaded rod,nuts, and washers. I made sure the bearings slid on the sleeve before installing them but once again when I get the bearings in the sleeve only goes in like 2 inches and then stops. Wtf seriously Idk what to do anymore it's not going in

Replied by tk11b40 on topic 1975 KZ 900 , ZRX Swingarm, 89 GSXR front end

09 Feb 2016 18:26

That is hard to do without the bike.

A straight

up stabilizer like this would be easiest, but I don't know what the travel needs to be, which of course depends on how and where we mount it.

www.motorcycle-superstore.com/56331/i/oh...steering-stabilizers

A straight

up stabilizer like this would be easiest, but I don't know what the travel needs to be, which of course depends on how and where we mount it.

www.motorcycle-superstore.com/56331/i/oh...steering-stabilizers

Replied by MAR on topic 1975 KZ 900 , ZRX Swingarm, 89 GSXR front end

09 Feb 2016 18:19

Let me know what would fit and I ll get it now . Not sure of how it would be mounted. I liked you idea under the headlight

Displaying 1161 - 1170 out of 7257 results.